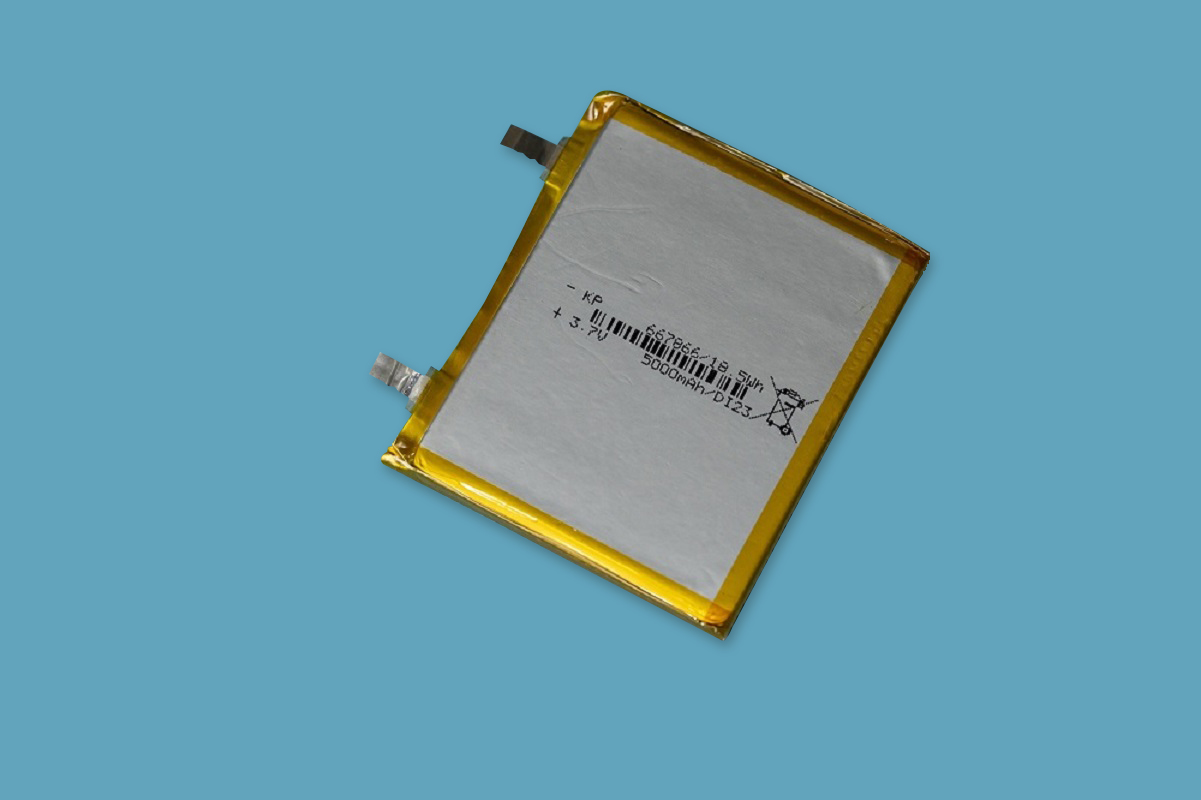

What are the advantages of polymer lithium batteries?(二)

2021-08-24 09:31:50

7. The thickness is small, and it can be made thinner. Ultra-thin, the battery can be assembled into a credit card. Ordinary liquid lithium batteries use the method of customizing the shell first, and then plugging the positive and negative materials. The thickness is below 3.6mm, and there is a technical bottleneck. Polymer batteries do not have this problem. The thickness can be below 1mm, which is in line with the demand for mobile phones nowadays.

8. Light weight, the battery using polymer electrolyte does not need a metal shell as a protective outer packaging. The weight of the polymer battery is 40% lighter than the standard steel shell lithium battery of the same capacity, and 20% lighter than the aluminum shell battery.

9. Large capacity, polymer battery is 10-15% higher than the steel shell battery of the same standard, and 5-10% higher than the aluminum shell battery. It has become the first choice for color screen mobile phones and MMS mobile phones. Most MMS mobile phones also use polymer batteries.

10. Small internal resistance

The internal resistance of polymer batteries is smaller than that of ordinary liquid batteries. Now the internal resistance of domestic polymer batteries can even be below 35mΩ, which greatly reduces the self-consumption of the battery and prolongs the standby time of the mobile phone. Level in line with international standards. This kind of polymer lithium battery that supports large discharge current is an ideal choice for remote control models, and has become the most promising product to replace nickel-hydrogen batteries.

11. The shape can be customized

The manufacturer is not limited to the standard shape, it can be economically made into a suitable size. The polymer lithium battery can add or reduce the thickness of the battery cell according to the needs of customers, and develop new battery cell types. The price is cheap and the mold opening cycle is short. Battery capacity.

12. Brief protection board planning

Due to the choice of polymer materials, the battery core does not catch fire or burst, and the battery itself has satisfactory safety. Therefore, the protection circuit planning of polymer batteries can consider saving PTC and fuses, and then saving battery costs.

-

skype

Zale Zhou